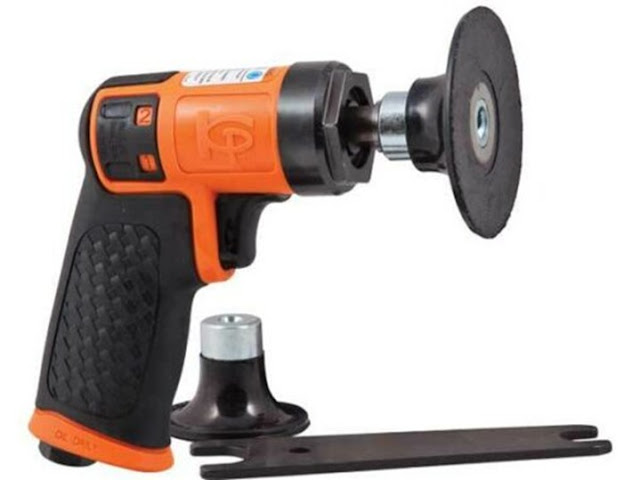

Even though sanding seems an easy option, but challenges could arise at any time, which cause frustration along with the flaws in the workpiece. The right commercial air sanders repairs can be done after you check the proper pressure technique, and you use multiple tools together to facilitate the repairing process. But in case if there is a need for the air sanders repairs as it shows issues such as swirls and other visual effects, you should first get it repaired before you proceed with the task.

If you want to get rid of these faulty air sander repairs, here are some tips that help sanders work smoothly for a longer duration.

1. Check The Air Pressure First

If the air sander is not performing well, then, first of all, you should check the flow of air pressure. You need to ensure that the sander's compressor provides sufficient air pressure to your sander for the perfect RPM (rotation per minute) speed. The compressor helps in determining the air pressure and to meet any type of requirement of each tool. Ultimately, swirls and other visual defects are mainly caused by the lack of proper air pressure in the air sanders. Hence, if the pressure is not right then you need to opt for air sanders repairs.

2. Check RPM

Usually, sanders are designed to run at a speed of 12,000RPM to 10,000 RPM. 10,000 RPM is a good start to achieve a good finish. With the age of the sanders, the RPM speed decreases if they are not appropriately maintained. While if you keep these well maintained, then the sanders speed will not get affected with age. Checking your sander’s RPM is essential if you want to have a consistent finish. You can use a tool named vibrating read tachometer to check the speed. If you find that the spinning is not working correctly, then you can try oiling. If anything like oiling does not work, then you should look for air sanders repairs.

3. Don’t Forget To Grease Or Oil The Sander Regularly

Is it possible to sand with a sander that does not move? Of course not, but again is it possible to do everything using your hands without a machine. In case if the sander stops working, then what will you do? Grease, oil and lubricants are some of the items that keep the air sanders work properly. Checking the backup pad quality and the range of sanding is also necessary in this direction. If there is lot of friction, the condition of the sander can be unbearable. Just keep it lubricated by adding 2-3 drops of machine oil into it. Remember that friction is not a friend of the sander; therefore, removing friction by using oiling is essential to keep your sander run smoothly and avoid air sander repairs.

4. Do not Forget To Pay Attention To The Backup Pads

One of the most overlooked areas of the sander is backup pads. Yes, it is easier to replace these, but what is the use of wasting your money on replacing them when you can keep them maintained and can keep your sander run smoothly. To increase the life of the backup pads, it is recommended you pay attention to them and clean them regularly. Make sure you also clean the residue present each time after the completion of the job.

Wrapping It Up:

Air sander repairs are unnecessary if you keep the sanders well maintained and pay attention to everything. Of course, nothing is more frustrating than this when your air sander stops working immediately. Prevention is always a better option.

Even though sanding seems an easy option, but challenges could arise at any time, which cause frustration along with the flaws in the workpi...